- Home /

- 3D Mobile Scanning Technology at Goodflex Rubber Company | Leading Rubber Hoses

Blog

3D Mobile Scanning Technology at Goodflex Rubber Company | Leading Rubber Hoses

At Goodflex Rubber Co, a prominent name among UK’s silicone hose manufacturers and suppliers, they consistently invest in cutting-edge technology. This empowers them to efficiently undertake and expedite high-value projects, including those involving rubber hoses.

3D Mobile Scanning Technology

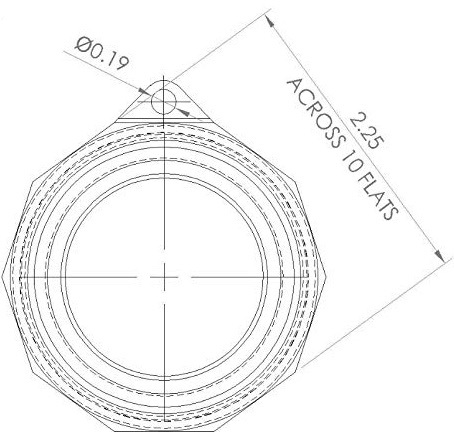

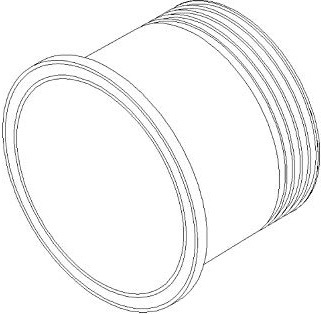

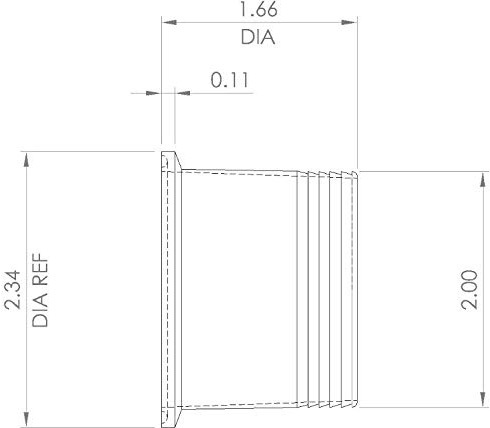

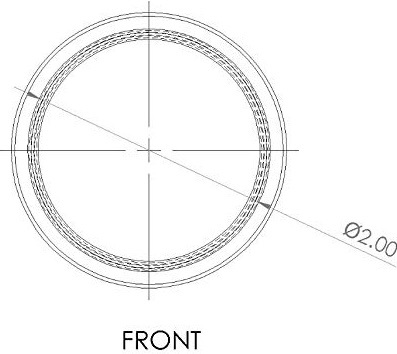

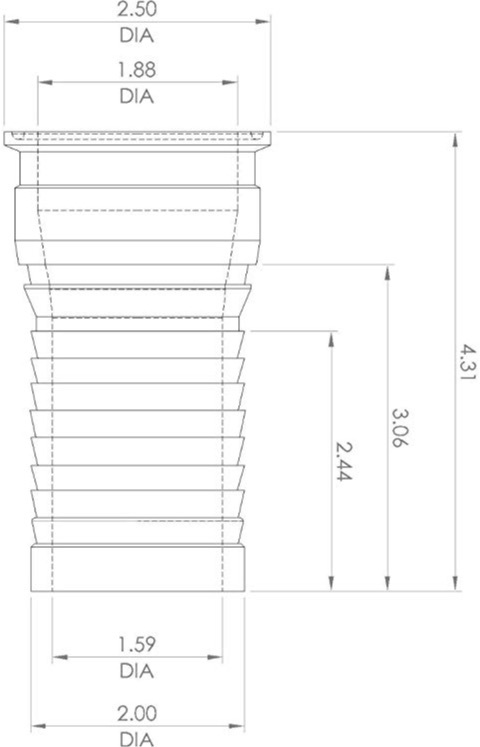

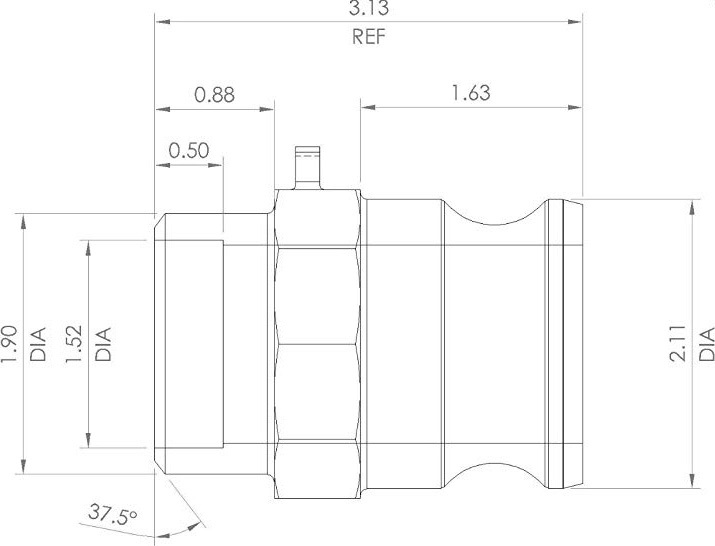

Having already invested in dedicated Solidworks CAD suites for the design of rubber hoses, mouldings, and assemblies, they are now supported by the latest 3D mobile scanning technology.

This enables Goodflex to rapidly reverse engineer components when 2D drawings or CAD models are simply unavailable. Or creating them would use valuable time and resource which the customer does not have.

The benefits of the latest hand-held 3D scanners include

- Superior Accuracy

- Ideal for Reverse Engineering

- Calibration Certification

- 0.1mm Resolution Capture for Fine Detail

It also means Goodflex can get it ‘right first time’, removing the trial and error and turning samples into accurate CAD models immediately.

The Latest 3D Scanning Software

The Goodflex 3D scanners use the latest software that handles the scanning process, the separate scan registrations and completes all the post-processing to mesh files. It also allows Goodflex to define CAD geometry alongside component point clouds and mesh data.

Choosing the Right Technology

Goodflex chose Peel 3D Scanners as they provide professional-grade handheld 3D scanning technology. This allows Goodflex to create high-quality 3D scans of small or large components whilst keeping customer projects within budget.

Scanning the Flattest Surfaces

Goodflex Rubber’s 3D Scanners can scan most items directly without any preparation as they recognise the shape of components automatically. They are also able to scan very smooth surfaces by using identification markers to scan the flattest surfaces.

A White Light-Based System

The scanners use a white light-based system and a scanning process based on the CLEANUP, ALIGN and MERGE methodology where the software removes the background and unwanted objects.

It then sets the origin of the model to the perfect location to use in a variety of other software. Followed by seamlessly combine several scans into one it can then be filled using three alternating features.

The scanners have been optimized to scan smaller parts and their smaller field of view provides them with a resolution of up to 0.1mm. This is further enhanced when used with a turntable, or they can be taken to a customer location and capture the finest of details in situ.

Ongoing Investment Programme

Commenting on the investment in the 3D scanners, Managing Director Mark Dufty said: “As part of Goodflex’s ongoing investment and R&D programmes we believe that this technology puts Goodflex at the forefront of our industry.

“It also means that we have the versatility to re-engineer parts with an incredibly rapid turnaround which is becoming even more important to our existing and new customers, especially in view of the issues with global supply chains at the moment.”

For more information contact the Technical Sales Team on 01386 841480 or email technical@goodflexrubber.com