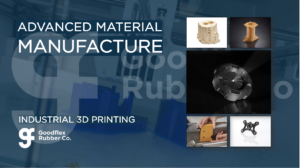

TIME TO ACCELERATE

ADVANCED MATERIAL 3D PRINTING SUITE

INNOVATE quicker and ACCELERATE your manufacturing by using our state-of-the-art 3D Printers. Using the latest Fused Deposition Modelling (FDM) and Fused Filament Fabrication (FFF) technology combined with access to the widest range of advanced additive materials.

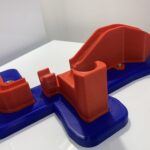

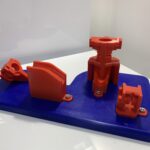

Our 3D Printing Technology is ideally suited for:

- Low Volume Production Parts

- Bridge-to-production Parts

- Rapid Prototyping

- Tooling

- Jigs and Fixtures

- Fit and Function Testing

With a high level of ACCURACY, SPEED and PERFORMANCE, our 3D printing solutions are fully supported by our CAD DESIGN TEAM, our 3D SCANNING for REVERSE ENGINEERING and are very competitive in terms of total cost.