EPDM Rubber

Ethylene Propylene Diene Monomer

Ethylene-propylene compounds are prepared from ethylene and propylene (EPM) and a third monomer diene (EPDM).

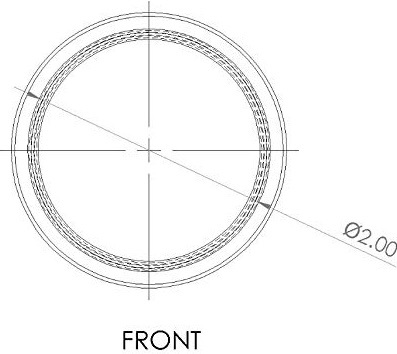

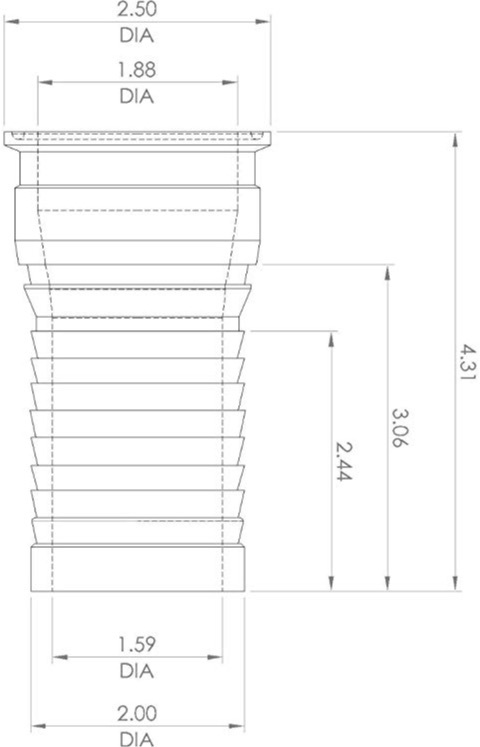

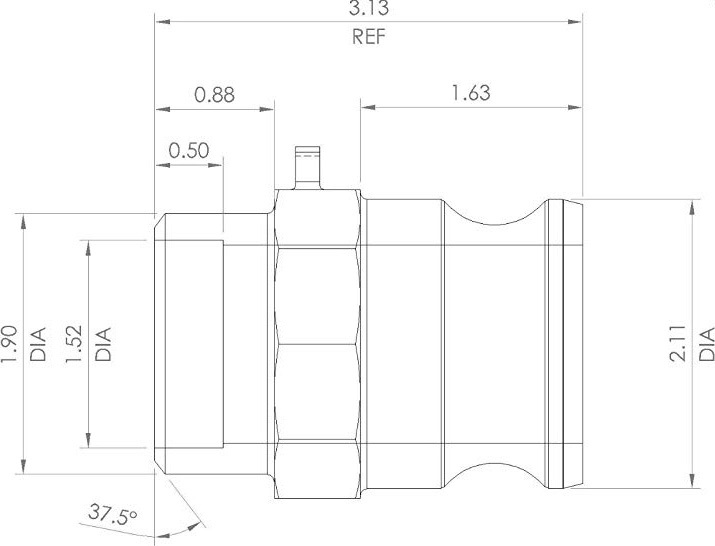

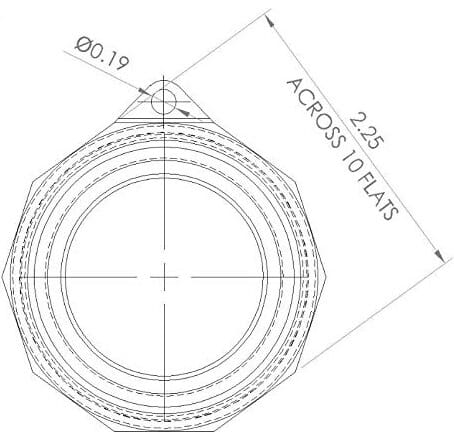

epdm hose manufacturer

Benefits of EPDM Rubber

Ethylene propylene compounds have excellent chemical resistance to mild acids, detergents and alkalis, silicone oils, greases and ketones, and alcohols. They are also compatible with many polar fluids.

EPDM compounds have excellent weather resistance, good low temperature flexibility but have poor petroleum oil and solvent resistance. They show good heat, ozone and ageing resistance.

EPDM can often be found in applications with brake fluids (based on glycol) and hot water. They are not recommended for applications with petroleum oils, mineral oil, di-ester lubricants, or fuel exposure.

EPDM compounds are typically developed with sulfur or peroxide cure systems. Peroxide cured compounds are suitable for higher temperature exposure and typically have improved compression set performance.

In addition they also exhibit high levels of elasticity, good low temperature behaviour as well as good insulating properties. The operating temperatures of applications for EPDM range between -45 °C/-49 °F and +150 °C/+302 °F (for a short period of time up to +175 °C/+347 °F).

With sulphur cured types the range is reduced to -45 °C/-49 °F and +130 °C/+266 °F (for short period of time up to +150 °C/+302 °F). It can be formulated for use between -40°C and 150°C and displays good dielectric properties. Sulphur cured for improved tear and tensile strength or peroxide cured to provide higher heat resistance.

As EPDM hose manufacturer, we use this elastomer for producing low density and light products. It is a cost effective solution for coolant and air hoses where there is a medium to high volume required. EPDM hose manufacturer

Excellent chemical resistance to mild acids, detergents and alkalis, silicone oils

Resistant to silicone oils, greases and ketones, and alcohols

Provides excellent compression set, tear, and abrasion resistance

EPDM compounds have excellent weather resistance and good low temperature flexibility

not recommended for applications with petroleum oils, mineral oil, di-ester lubricants, or fuel exposure.

Case Studies

We Work with Leading Companies and High Performance Teams within Engineering and Procurement

Here are some Case Studies of Companies that Goodflex Work with Day to Day