AEM Rubber - Vamac ©

Ethylene-acrylic monomer is a terpolymer of ethylene, methyl acrylate

and an acid-containing monomer as a cure site.

Benefits of AEM Rubber - Vamac ©

Ethylene-acrylic monomer is a terpolymer of ethylene, methyl acrylate, and an acid-containing monomer as a cure site.

It is the modern alternative to HNBR but far more cost effective. It is also the perfect alternative when you want to use NBR or PVC/NBR but with a higher and lower operating temperature than nitrile whilst still giving excellent oil resistance.

AEM can replace silicone in certain applications especially high volume requirements where economies of scale are required.

AEM Ethylene Acrylic Elastomer offers high heat resistance, excellent ozone and weather resistance, low temperature flexibility and high tensile strength as the polymer backbone is fully saturated.

It also has excellent vibration dampening, excellent heat aging characteristics and good dynamic property retention over a wide, temperature range.

Because of the acrylic monomer it is resistant to oils, transmission fluids, water, glycol mixtures, and alkalis.

AEM is resistant to heat up to 150°C and has a low temperature resistance between -29°C and -40°C. The balance of ethylene and acrylic monomer in the polymer determines the low-temperature properties.

It is not suitable for use with ketones, fuels, brake fluids, aromatic hydrocarbons or phosphate esters.

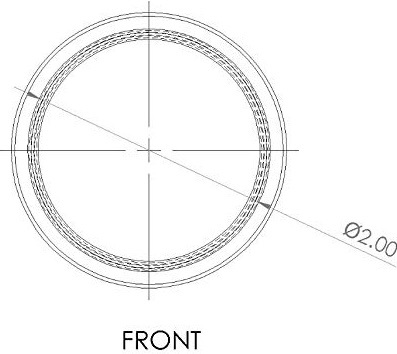

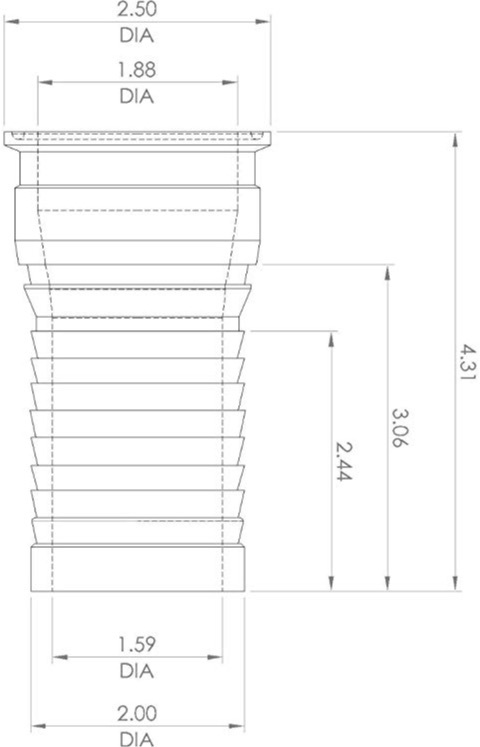

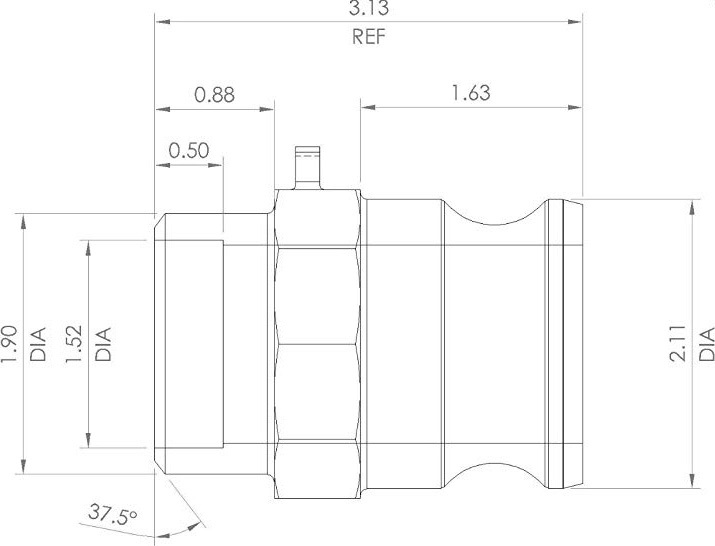

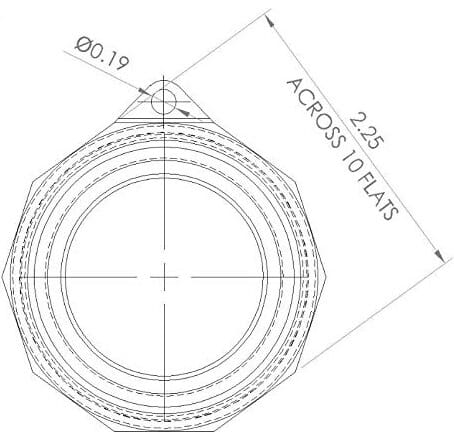

Typical applications are air management, vacuum and engine breather and oil hoses to meet the high modern under bonnet temperatures including high volume air intakes where EPDM does not meet temperature requirements. It is also used for de-aeration hoses and certain charge air cooler systems.

AEM rubber is the modern alternative to HNBR but far more cost effective.

AEM is resistant to heat up to 150°C and has a low temperature resistance between -29°C and -40°C

AEM suitable for use with ketones, fuels, brake fluids, aromatic hydrocarbons or phosphate esters.

Typical applications are air management, vacuum and engine breather and oil hoses

AEM Ethylene Acrylic Elastomer offers high heat resistance, excellent ozone, weather resistance, low temperature flexibility and high tensile strength

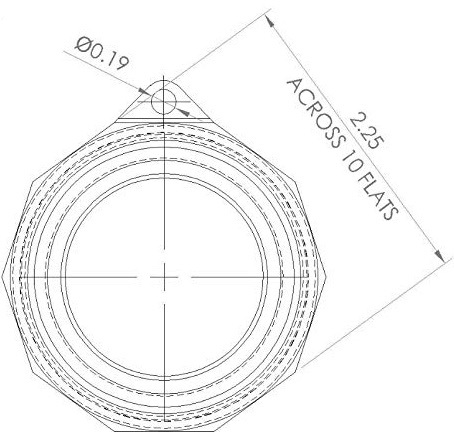

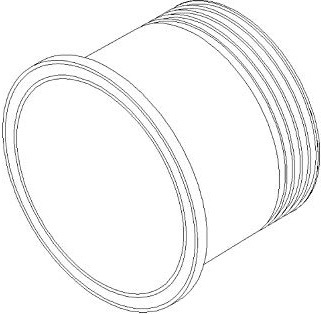

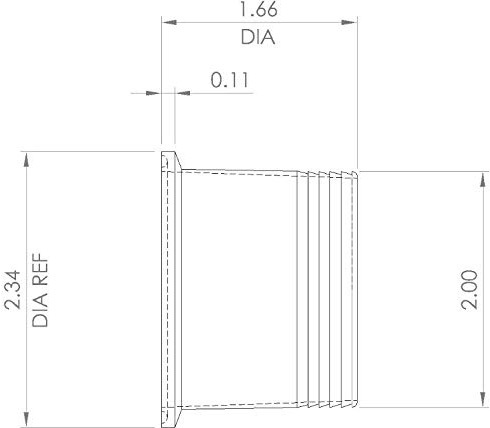

AEM - Vamac © Rubber Products

Case Studies

We Work with Leading Companies and High Performance Teams within Engineering and Procurement

Here are some Case Studies of Companies that Goodflex Work with Day to Day