Nitrile Butyl Rubber

Nitrile is a copolymer of butadiene and acrylonitrile

Variation in proportions of these polymers is possible to accommodate specific requirements.

Benefits of Nitrile Butyl Rubber

Nitrile is a copolymer of butadiene and acrylonitrile. Variation in proportions of these polymers is possible to accommodate specific requirements.

On a cost basis nitrile rubber is the least expensive of the oil resistant elastomers. The popularity of nitrile is due to its excellent resistance to petroleum products and its ability to be compounded for service over a temperature range of -22°F to 212°F.

The properties of the Nitrile Rubber depend mainly on the acrylonitrile content which ranges between 18 % and 50 %. In general they show good mechanical properties. An increase in acrylonitrile content increases resistance to heat plus petroleum base oils and fuels but decreases low temperature flexibility.

Nitrile provides excellent compression set, tear, and abrasion resistance. The major limiting properties of nitrile are its poor ozone and weather resistance and moderate heat resistance, but in many applications these are not limiting factors.

The operating temperatures range between -30 °C/-22 °F and +100 °C/+212 °F (for a short period of time up to+120 °C/+248 °F). Suitable formulated NBR can be used down to -60 °C/-76 °F. NBR is mostly used with mineral based oils and greases.

Nitrile is resistant to fuel, oil, lubricants and shows resistance to ageing, fatigue and abrasion. It has excellent petroleum, oils, silicone, fluids and water resistance along with good dilute acids, dilute alkalis, hydraulic fluids and transmission fluids resistance. NBR can also be hydrogenated to increase its temperature range.

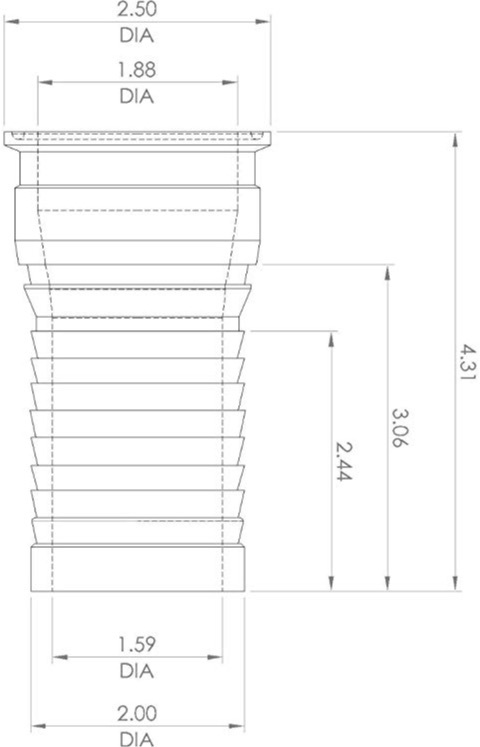

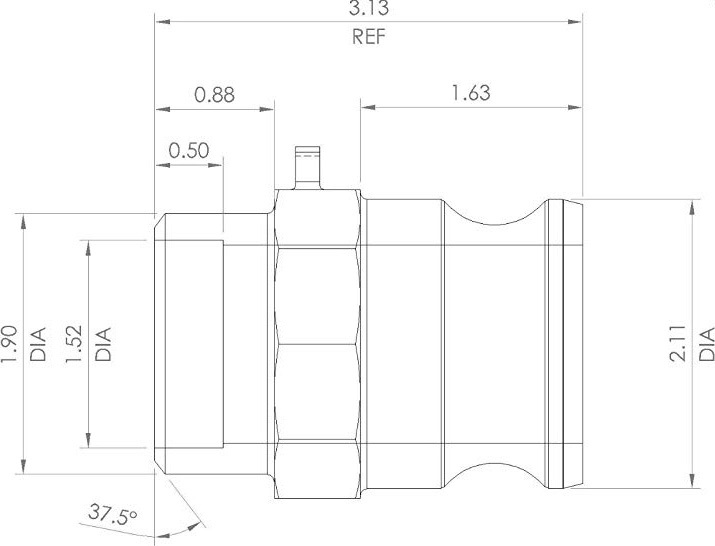

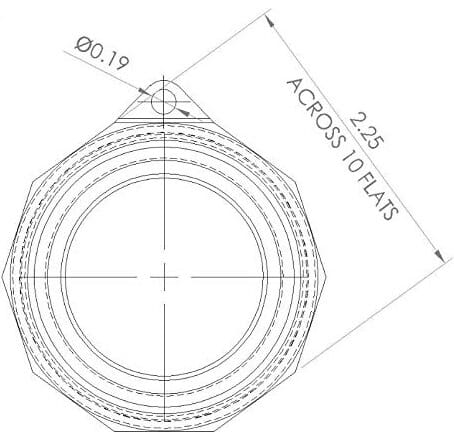

Nitrile is an established material for use in fuel or oil applications i.e. filler, reservoir and engine breather hoses.

On a cost basis nitrile rubber is the least expensive of the oil resistant elastomers

The popularity of nitrile is due to its excellent resistance to petroleum products

Nitrile provides excellent compression set, tear, and abrasion resistance.

The operating temperatures range between -30 °C/-22 °F and +100 °C/+212 °F (for a short period of time up to+120 °C/+248 °F)

The major limiting properties of nitrile are its poor ozone and weather resistance

Case Studies

We Work with Leading Companies and High Performance Teams within Engineering and Procurement

Here are some Case Studies of Companies that Goodflex Work with Day to Day