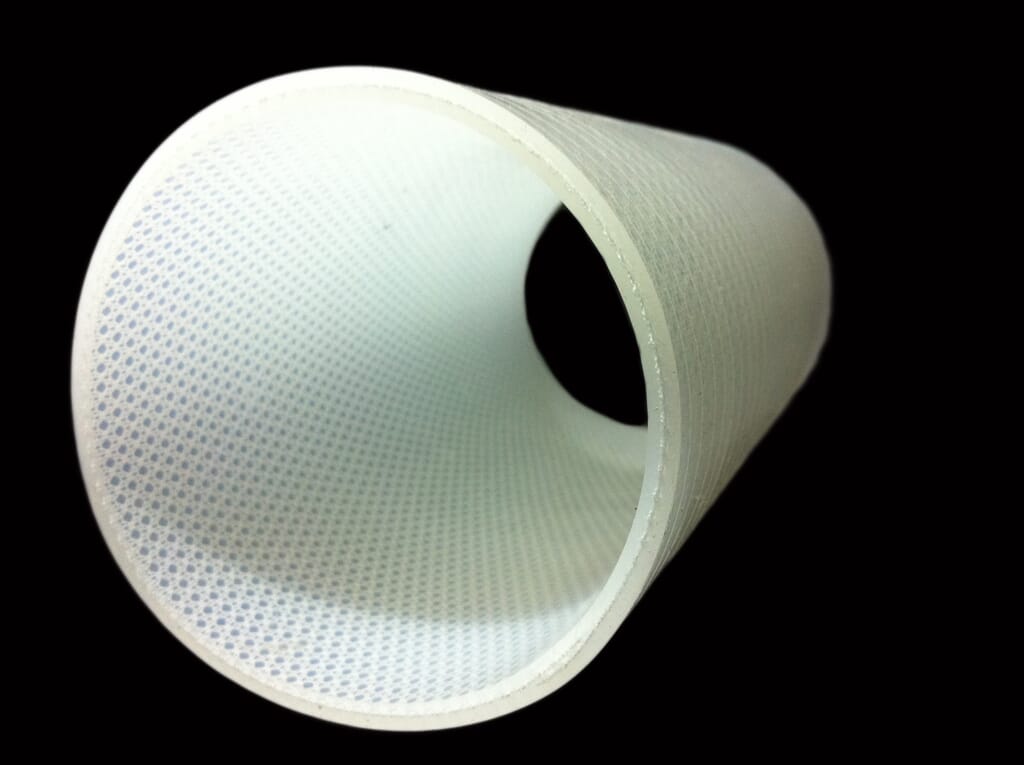

Food Grade Silicone

FDA approved VMQ has reduced food taint and very low bacteria build up resulting in ultimately lower maintenance costs.

Food grade silicone formulations are designed specifically for use with food products

Benefits of Food Grade Silicone

Food grade silicones are a group of elastomeric materials made from silicone, oxygen, hydrogen, and carbon that display extreme temperature range and low temperature flexibility.

Food grade silicone utilizes a flexible siloxane backbone rather than a carbon backbone like many other elastomers and has very low glass transition temperatures.

Food grade silicones show excellent heat resistance, cold flexibility, dielectric properties and especially good resistance to weather, ozone and UV rays.

Food grade silicone formulations are designed specifically for use with food products. FDA approved VMQ has reduced food taint and very low bacteria build up resulting in ultimately lower maintenance costs.

The temperature range is between -50 °C/-58 °F and +175 °C/+347 °F (temporary up to +230 °C/+446 °F).

Food grade silicone can be reinforced with polyester and wire if required to withstand pressures as with standard grade silicones.

Food grade silicone formulations are designed specifically for use with food products.

FDA approved VMQ has reduced food taint and very low bacteria build up resulting in ultimately lower maintenance costs.

The temperature range is between -50 °C/-58 °F and +175 °C/+347 °F (temporary up to +230 °C/+446 °F).

Food grade silicone can be reinforced with polyester and wire if required to withstand pressures as with standard grade silicones

Displays extreme temperature range and low temperature flexibility.

Case Studies

We Work with Leading Companies and High Performance Teams within Engineering and Procurement

Here are some Case Studies of Companies that Goodflex Work with Day to Day