EPDM Hose - Reducing Hose

EPDM Hose – Reducing Hose for a wide range of applications requiring high and low temperature flexibility and excellent resistance to ozone, UV and moisture. CALL NOW

PRODUCT INFORMATION

EPDM Hose – Reducing Hose have fair tensile strength and excellent UV and Ozone resistance. EPDM can be formulated to meet the latest Electro Chemical Degradation requirements in the Automotive industry. EPDM shaped hoses can be designed to suit any unique application. Suitable for a wide range of applications that require high and low temperature flexibility with excellent resistance to ozone, UV and moisture. Goodflex will advise the optimum material specification, reinforcement and construction for your specific application.

STANDARDS

We are able to manufacture EPDM Hose – Reducing Hose to meet most industry standards

APPLICATIONS

EPDM Hose – Reducing Hose are available for multiple applications.

CONSTRUCTION CHARACTERISTICS

EPDM Hose – Reducing Hose are dual extruded with braided reinforcement and mandrel cure (sulphur or peroxide)

TYPICAL SIZES

EPDM Hose – Reducing Hose are available between 8mm – 76mm (unreinforced 101mm)

TEMPERATURE RANGES

EPDM Hose – Reducing Hose operate at -50˚C to 130˚C

WORKING PRESSURES

EPDM Hose – Reducing Hose havae an operating pressure 3 bar with a burst pressure of 8 bar.

COLOURS

EPDM Hose – Reducing Hose are available in black

DON’T FORGET

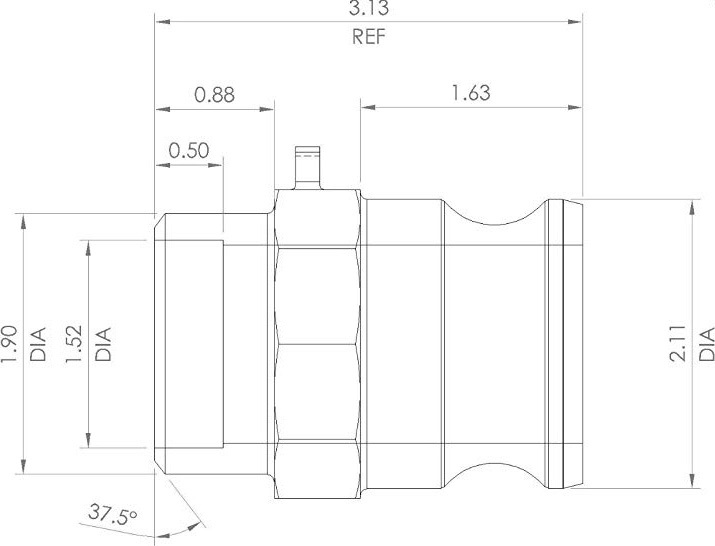

For EPDM Hose – Reducing Hose, send us your sample, 2D drawings or 3D CAD models so that we can advise the most cost effective solution.

Get a Free Quote

EPDM Hose - Reducing Hose

Product Details

EPDM Hose – Reducing Hose for a wide range of applications requiring high and low temperature flexibility and excellent resistance to ozone, UV and moisture. CALL NOW

PRODUCT INFORMATION

EPDM Hose – Reducing Hose have fair tensile strength and excellent UV and Ozone resistance. EPDM can be formulated to meet the latest Electro Chemical Degradation requirements in the Automotive industry. EPDM shaped hoses can be designed to suit any unique application. Suitable for a wide range of applications that require high and low temperature flexibility with excellent resistance to ozone, UV and moisture. Goodflex will advise the optimum material specification, reinforcement and construction for your specific application.

STANDARDS

We are able to manufacture EPDM Hose – Reducing Hose to meet most industry standards

APPLICATIONS

EPDM Hose – Reducing Hose are available for multiple applications.

CONSTRUCTION CHARACTERISTICS

EPDM Hose – Reducing Hose are dual extruded with braided reinforcement and mandrel cure (sulphur or peroxide)

TYPICAL SIZES

EPDM Hose – Reducing Hose are available between 8mm – 76mm (unreinforced 101mm)

TEMPERATURE RANGES

EPDM Hose – Reducing Hose operate at -50˚C to 130˚C

WORKING PRESSURES

EPDM Hose – Reducing Hose havae an operating pressure 3 bar with a burst pressure of 8 bar.

COLOURS

EPDM Hose – Reducing Hose are available in black

DON’T FORGET

For EPDM Hose – Reducing Hose, send us your sample, 2D drawings or 3D CAD models so that we can advise the most cost effective solution.

Full Design Support

We respond every time, with full design support from you multi disciplined engineering team

Reduced Time for New-Part-Introduction

We reduce the time for new part introduction and improved ‘time to market’ to your customers

Global Manufacturer & Supplier

We are a global manufacturer and supplier of rubber hoses, moldings and assemblies that perform for the entire product service life

Achieve Budget Targets

We are a global manufacturer and supplier of rubber hoses, mouldings and assemblies that perform for the entire product service life

Shorter Lead Times

We supply shorter lead times for ‘at speed’ and ‘on time’ delivery to minimise impact on your business

Instant Access to Goodflex Experts

We give you instant access to our customer service, technical and engineering experts